ball mill working principle YouTube

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Ball Mill Design/Mineral Ball Mill/Grate Ball Mill/Overflow Type Ball Mill Except there is a discharging grate plate installed at the discharging end, all the other is similar with the overflow ball mill.

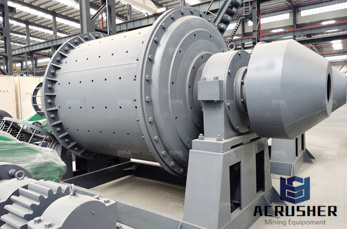

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼" to ". The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition.

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . Ball and Pebble Mills: The expressions "ball milling" and "pebble milling" are frequently used interchangeably. Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses

Nov 18, 2008· Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls) put in the shell, and has a simple structure and ease of handling. Furthermore, The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wet 14. References 1.

Jul 26, 2019· Great Wall Steel Casting (CHAENG) can produce ball mill trunnion / ball mill cover / ball mill head according to drawings.

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Ball Mill Cover. Steel Castings for Grinding Mills Ball Mill Cover. Mill cover is an important part of the grinding mill, which supporting and connection the mill shell. Mill cover is the feed and discharge passage of the materials. Ball mill cover: 1. Material: ASTMA .

The key components of the ball mill are the rotary body containing the material, which is composed of the feed part, the cylinder part and the discharge part, and the end cover is the key part in the inlet and outlet parts, which is divided into the feed end cover and the discharge end cover. After one year of operation of an overflow ball mill, cracks appear at the root of the end cover, and ...

Mar 14, 2007· As an engineer who has experience using FEM for the design and assessment of SAG and ball mill foundations, I know that this approach can be timeconsuming, costly and in some cases not even a hope of being accurate if you don''t have appropriate geotechnical and .

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Ball mill end cover (ball mill head) is one of the key components of the ball mill, located at both ends of the ball mill cylinder and is supported on the bearing, mainly used to support the material, the cylinder and the medium. CHAENG can manufacture ball mill end cover (ball mill head) according to .

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications.

Jul 25, 2019· CHAENG is specialized in manufacturing large steel casting parts for ball mill: ball mill trunnion, ball mill main bearing, ball mill bearing pedestal, ball mill girth gears and so on (see more ...

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as .

Feb 12, 2017· In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

DESIGN. NEWS. CONTACT US. Metallurgical machinery Cement machinery Mining machinery Gear products Nonstandard mechanical parts Wear resistant parts ...

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Feb 18, 2019· Dec 04, 2012ball mill foundation design. Home ball mill foundation design. sbm company is a research and development, production, For the foundation design and . ball mills foundations design ...

WhatsApp)

WhatsApp)