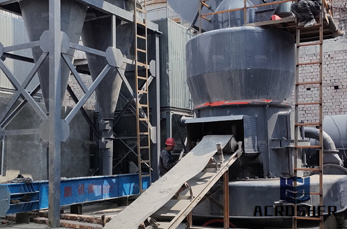

Grinding Mill

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

WhatsApp)

WhatsApp)

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Coal Mills in thermal power plant Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. for thermal powerplant familiarization. ... TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind.

Mill power Usually, plant operators use mill power readings as an indicator of ball filling degree and, often, try to keep it at the maximum level. It is well known that the mill absorbed power depends on operating parameters other than ball level, such as pulp density and liner configuration.

Sep 11, 2013· ball mill coal burning power plant COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR . Dec 13, 2011 · This website will provide the most useful technical information about COAL BASED THERMAL POWER STATIONS particularly for power engineers . Coal Fired Power Plant Manufacturers, High Quality Coal Fired ... Coal Fired Power Plant, Coal Fired Power Plant.

A typical comparison of three competing technologies is given in Table 1, demonstrating that an efficient ball mill/thirdgeneration separator, CKP/ball mill/thirdgeneration separator and vertical mill on a typical 4000Blaine limestone cement show little overall difference in energy consumption.

Ball Mill For Power Plant. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Ball Mill Popular Coal Mill in Powder Plant. Because coal is the main purpose of fuel for power plants, and so will usually choose Ball Mill as a coal Mill in powder plant, Ball Mill, Ball Mill, the performance characteristics of Ball Mill for the edge of the transmission, by the motor through reducer, and the size of the gear drives the Mill ...

Function Of Ball Mill In Power Plant

•Concern was expressed over the gearbox and Ball Mill at a power plant. •Black grease was noticed at the couplingend pillow block bearing as well as a loose bearing nut. •Unusual noises were also reported from the machine. •The gearbox between motor ball mill had been recently rebuilt.

The ball mill is the most common ore grinding technology today, and probably more than 50% of the total world energy consumption for ore grinding is consumed in ball mills.

Dec 13, 2011· Ball mills are always preferred to be operated at full capacity because the power consumption of this type of mill is very high at lower loads when compared with other types. Ball mills can be designed for a very high capacity like 75 tons per hour output for a specific coal.

Ball Mill In Thermal Power Plant t Ball Mill In Thermal Power Plant. Ball mills may not be the most efficient means of size reduction but their reputation for product consistency and their simplicity of operation have made them an historic plant favoriteince the 1980s, Cement plants are increasingly looking to vertical roller mill

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal .

Ball Mill Popular Coal Mill in Powder Plant Because coal is the main purpose of fuel for power plants and so will usually choose Ball Mill as a coal Mill in powder plant Ball Mill Ball Mill the performance characteristics of Ball Mill for the edge of the transmission by the motor through reducer and the size of the gear drives the Mill . Online ...

Jan 04, 2016· Amazing Fastest Homemade Wood Lathe Machines Working Skills Extreme Wood Cutting Machines Easy Duration: 16:01. Machine VT Recommended for you

Ball mill operation in power plant . ball mill operation in power plant ball mill in power plant spirosurvey. ball mill of thermal power plant grinding mill equipment jan 252014 this is the first mathematical model of power plant tubeball mills to4the heat input into the coal mill and the heat output from the coal mill.

of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a mathematical model for autogenous, semiautogenous and ball mills which is based on the motion of grinding charge inside the mill.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

ball mill of power plant ball mill is efficient in power plants. ball mill is efficient in power plants Tidal power Tidal power or tidal energy is a form of hydropower that converts the energy obtained from tides into useful forms of power, mainly electricity Although not .

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as .

ball mill of thermal power plant Get Price And Support. Simply complete the form below, click submit, you will get the price list and a SBM representative will . Ball Mill In Power Plant. Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball Mills are used wherever the .

Oct 12, 2017· In ancient time, the mills were operated with muscle power (by hands), water animals and wind. They were totally based on the mechanical energy by natural resources and living are many types of mills which are used in the grinding industries. Today we will discuss about two important mill, sag mill and ball mill.

By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inch) diameter schedule 40 type 316 stainless steel pipe and would be about 38 cm (15 inches) long. The plans show stainless steel grinding rods for this size of mill may be a graduated charge from 25 to 10 mm diameter (1 inch to 1/2 inch) but variations in size are not ...

WhatsApp)

WhatsApp)