ball mill rod mill cement pdf

Mill Price or a Rod Mill PriceGrinding RodsGrinding BallsWhat is the Steel Charge of a Ball MillDifference Between a Rod Mill and Ball MillHow ... cement, lime ...

WhatsApp)

WhatsApp)

Mill Price or a Rod Mill PriceGrinding RodsGrinding BallsWhat is the Steel Charge of a Ball MillDifference Between a Rod Mill and Ball MillHow ... cement, lime ...

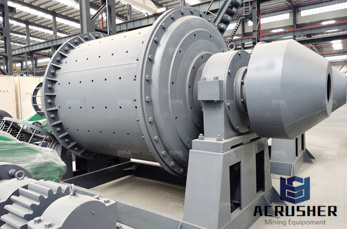

Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Ball mills are widely used in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing and glass and ceramics industries. Rod mill. Brief introduction The rod mill is a kind of equipment with professional crushing materials as fixed particles. It is basically the same as the ...

Cement Boll Mill Details Pdf. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding timeshe PM 100 is a convenient benchtop model with 1 grinding stationou may also be interested in the High Energy Ball Mill

Anyang General International Co., Ltd. (AGICO Group) is a ball mills supplier. Our company is mainly engaged in the development, design, manufacture, installation and commissioning of various mining and cement milling equipment and a complete set of the industrial grinding line.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the ... steel balls in a ball mill, or large lumps of ore in an

Dec 30, 2012· That being said, here are a few links I found for building your own ball mill, a rod mills would be build much the same but using heavy rods instead, old truck axles would be a great source for a small rod mill, with a ball mill or a rod mills having different sizes of grinding medium would work better than having all of the same size balls/rods.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd., New Delhi ABSTRACT Grinding technology has been continuously improving with numerous innovations with a view to improve productivity and reduce power consumption.

Ball Mill Maintenance In A Cement Factory. Ball Mill repair and maintenance are crucial for,XSM is a professional manufacturer of grinding mills and stone crushers(pdf ball mill maintenance), such as gold mining equipment, coal mining equipment, surface mining equipment, underground mining equipment and other quarry mining equipmentsXSM is a ...

F 80 is the mill circuit feed size in micrometers. Rod mill. A rotating drum causes friction and attrition between steel rods and ore particles. [citation needed] But note that the term ''rod mill'' is also used as a synonym for a slitting mill, which makes rods of iron or other metal. Rod mills are less common than ball mills for grinding minerals.

Design and Optimization of Ball Mill for Clinker Grinding. Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. Sanjeev T. .... specific energy requirement for clinker grinding ~ 40 kWh / Ton in ball mill before this study and 30. kWh/T now ... P_Grinding_Operations_ ). 3. Read More

The difference between ball mill and rod mill . 1. Shape and structure. The ratio of tube length to diameter of the rod mill is generally, and the inner surface of the lining plate on the end cover is vertical plane. The ratio of cylinder length to diameter of ball mill is small, and in most cases the ratio is only slightly greater than 1.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

Ball mill Wikipedia, the free encyclopedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory . Get Price; This list of test equipments for physical amp;

The ball mill and the rod mill are the most commonly used grinding equipment in the dressing plant, so what is the difference between the operation of the two grinding equipment? Sometimes we think, why do we have a ball mill for a dressing plant, but with a rod mill, why? Today we analyze the problem from the point of view of the operation. to make a difference

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

The product size distribution is narrower than a ball mill but significantly coarser. Most are overflow discharge type. Lengthtodiameter= to Mill length = 7 meters. Rod MillBall Mill Circuits Diagrams of mill circuits [image: (13582)]

Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single stage circuit. Rod ball mill sizing: Calculator for rod mill(s) as first stage of the circuit and ball mill(s) as second stage of the circuit.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

Improvements in Cement Ficem. clinker 90 130 kWh / t cement in a modern plant, more for older or less efficient .... new cement mill. Ball mill in closed circuit. BM + RP. (comb. grinding). VRM .... Difference between good poor mill operation maintenance can results in. Get Price

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

How to Make Milling More Energy Efficient Siemens. create Portland cement clinker, the basic material for all types of cement. The next step is to grind the clinker in a ball mill .

Rod Mill is different with Ball Mill. 1. Grinding media of Rod mill are steel bars. ball mill use of steel balls as grinding media. 2. Rod mill is suitable for coarse grinding, when product granularity is between 1 to 3mm, processing capacity of rod mill is bigger than ball mill with same specification. 3.

WhatsApp)

WhatsApp)