Proses Leaching Pilot Plant YouTube

Sep 17, 2018· Menjelaskan proses leaching pada pilot plant. How to create a 3D Terrain with Google Maps and height maps in Photoshop 3D Map Generator Terrain Duration: 20:32. Orange Box Ceo 8,369,077 views

WhatsApp)

WhatsApp)

Sep 17, 2018· Menjelaskan proses leaching pada pilot plant. How to create a 3D Terrain with Google Maps and height maps in Photoshop 3D Map Generator Terrain Duration: 20:32. Orange Box Ceo 8,369,077 views

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Leaching, often gold, is the process of extracting a soluble constituent from a solid by means of a solvent. In extractive metallurgy, of gold, it is the process of dissolving a certain mineral (or minerals) from an ore or a concentrate, or dissolving certain constituents from materials such as a calcines, mattes, scrap alloys, anodic slimes, etc., to achieve either one or two purposes ...

Optimised pilotplant leaching results Parameter Peñoles Harmony Leaching time (h) 2–3 2 Gold leaching efficiency (%) Gold concentration of feed material (%) 67 Gold concentration in leach liquor (g/l) 74 65 Fraction of initial gold reporting to residue (%) Gold concentration of residue (%) Table IV

The following estimates are for countercurrent decantation cyanide circuits and are based on average grade ore requiring average treatment time. These include precipitation and accessory equipment. The equipment required for a cyanide plant will vary considerably with the value of the ore, the settling rate, the chemical composition of the ore, the hardness, and the degree of grinding ...

Getting more out of copper, zinc and gold resources . At a pilot plant facility at FL''s technology centre in Salt Lake City, USA, over 250 batch leach tests have been completed in 10 and 100 litre reactors, using copper concentrates from over thirty different sources.

The model then predicted the profiles of gold in solution and on the carbon that would be achieved in the pilot plant at steady state. The results are presented in Table 7, and show that the model provided a good simulation of the future pilot plant performance.

A number of commercial installations have arisen along with numerous pilot plant tests. The stateoftheart development of the treatment of copper–gold concentrates using hydrometallurgical methods is reviewed. ... Successful leaching of gold requires a sufficiently high oxidation potential to form the auric tetrachloride complex species ...

Factors influencing the rate of gold cyanide leaching and adsorption on activated carbon, and their impact on the design of CIL and CIP circuits

plant design for leaching gold with thiourea . have inaugurated a pilot plant to leach gold and silver ore UAM unveil pilot thiourea AuAg . Get Price And Support Online; Sepor Pilot Plants | Sepor. Sepor Pilot Plants. SEPOR, INC . The use of pilot plant testing is to demonstrate and more importantly confirm that the process flow .

desing of mobil gold leaching plant; ... and provides for the possible recovery of other minerals by gravity concentration The flowsheet is ideal for a pilot plant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

gold leaching pilot plant Gold CIL CIP Gold Leaching Process Explained CCD. The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon. CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching ...

Feb 21, 2014· TCB International LLC is a Phoenix, Arizona based company specializing in the processing of precious metal ores. Our state of the art plant contains an in house laboratory and leaching facility.

A process has been evaluated, on a continuous pilot plant scale, to treat refractory gold arsenopyrite/pyrite . concentrates. The process consisted of biological leaching to partially oxidise sulphides, followed by pressure leaching for complete sulphide oxidation and arsenic precipitation, followed by liquor neutralisation and

The process is particularly well suited for treating refractory gold ores, which give low recovery when directly leached with cyanide. SGS is a world leader in batch and pilot plant testing and flowsheet development for pressure oxidation processing.

Stirred slurry preheat pilot plant Advance your mining and hydromet process technology towards commercialization by working with leading experts. Our team''s experience and dedication are incomparable when it comes to pilot plant projects of quality, unique solutions, and above all – results.

Metallurgical ContentLeaching Gold CircuitsTypical Gold Milling Flowsheets Gold Leaching Equipment LayoutEasy Gold Plant and Business Expansion In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine. The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding .

Test Work Results from Porgera Joint Venture Gold Plant A range of test work was carried out by ConSep on site at Porgera. The final test work conducted consisted of four leach tests carried out with varying reagent addition rates. Test PC1 Aiming to determine leach recovery with no accelerant addition, Air only leaching.

While copper bacterial leaching thus far has been confined to the leaching of ore, pilot plant tests are underway for the leaching of chalcopyrite concentrates that would normally be processed by smelting. ... How Hydrometallurgy and the SX/EW Process Made Copper the "Green" Metal;

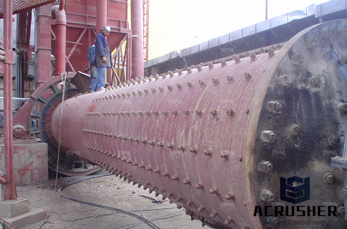

Gold Leaching Pilot Plant. Gold Leaching Equipment, Circuits Process Plants. Metallurgical ContentLeaching Gold CircuitsTypical Gold Milling Flowsheets Gold Leaching Equipment LayoutEasy Gold Plant and Business . Pilot Plant Design; Get Price And Support Online; HEAP LEACHING TECHNIQUE in MINING. Heap leaching is a tried and tested mining ...

Laboratories and Pilot Plants Muir Introduction It is generally accepted in the gold mining industry in South Africa that effi cient, ongoing metallurgical support should be provided for plant operations. At the same time, it is essential that research be undertaken to improve cur rent process steps and"to develop new techniques.

Oct 20, 2014· Nature of Gold: The surface of a gold particle will typically be dissolved at a rate of around µm of surface depth per hour in a cyanide leach. For large gold particles and nuggets, this is too slow to be fully dissolved in a typical processing plant. Much simpler and less expensive gravity methods are available to recover this gold.

Cyanide leaching has been the industry standard for gold processing for more than 100 years. During the cyanide leach process, a cyanide solution, or lixiviant, is percolated through ore contained in vats, columns or heaps. Gold is dissolved by the cyanide and then removed from the heap or columns.

THIOUREA Rein * LEACHING OF GOLD Robert IN A CONTINUOUS PILOT PLANT Raudsepp* and Allgood** Ltd., 2036 Columbia Bacon Donaldson and Associates Street, Vancouver, V5Y 3 E 1 ** S o n o r a Mining C o r p o r a t i o n, Box 1418, Highway 108, Jamestown, C a l i f o r n i a Highschool 95327 Road, ABSTRACT Sonora pyritic gold concentrate was continuously leached in a twostage thiourea pilot ...

WhatsApp)

WhatsApp)