Gold Processing Mill YouTube

Oct 26, 2011· Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. ... Mobile Gold Mill For HardRock Ore ... Flotation For Gold Ore ...

WhatsApp)

WhatsApp)

Oct 26, 2011· Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. ... Mobile Gold Mill For HardRock Ore ... Flotation For Gold Ore ...

APPLICATION OF FLOTATION TO GOLD ORE. A flotation plant is being erected at the Falcon mine, Rhodesia, to treat ore containing gold and copper. With the exception of the Mt. Morgan, the Etheridge, and the Great Fitzroy mines, Queensland, I have not heard of the flotation process being used successfully to treat ore containing an appreciable amount of gold.

Harte Gold Corp. is Ontario''s newest gold producer through its wholly owned Sugar Zone Mine in White River Ontario . MILL OPERATOR (Grinding/Flotation) We are seeking energetic and selfmotivated individual to fill this position.

Gold flotation process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation reagent to make the useful mineral adhere to the bubble to achieve the purpose of gold extraction. Gold Flotati...

There are many arrangements and combinations using flotation in conjunction with treatment of gold ores. The two gold process flowsheets shown, with some variations, are probably the most commonly used.. In Gold Flowsheet No. 1 the ore is ground in water to such a size as to free the minerals sufficiently to produce a tailing by flotation low enough in value that it may be discarded.

Aug 03, 2019· The addition of lime in the flotation operation is usually carried out by adding the lime powder to the ore belt of the ball mill or adding lime milk or lime powder to the stirring tank before the flotation. The role of lime in the flotation process is most apparently the effect on the properties of the flotation .

gold cil and cip plant design; granite grinding mineral manufacturer in chennai; energy saving grinding mill machine; ore dressing ore circle vibrating screen; agitated tank process gold; ore dressing ore wertical two roll mill; gold ore grinder plant sweden

Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99%. Gold CIL Processing Line

Gold Cyanide Process. Gold Cyanide Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

250 T H Flotation Cell Ball Mill For Gold Ore Production Plant . 200 tph gold flotation cell plant explanation50 180 tph gold ore crushing plant lotation cell in iron ore benificiation 20 tph 50 tph 100 tph 200 tph jaw crusher plant with aw crusher is the traditional product in crushing and beneficiation plants it is suitable for crushing a variety of soft and hard ores and rocks ...

Harte Gold Corp. is Ontario''s newest gold producer through its wholly owned Sugar Zone Mine in White River Ontario . MILL OPERATOR (Grinding/Flotation) We are seeking energetic and selfmotivated individual to fill this position. The successful candidates will have a high focus on safety and environmental protection in all aspects of the job.

ore pulp. Flotation, as developed in the twentieth century, has now become the most widely used proc ess for extracting minerals from metallic Development of Flotation N ineteenthcentury mill men acknowledged that current milling practices,, crushing, gravity con .

The ores from which silver and gold are recoverable by flotation divide themselves naturally into two general processing classes: ores in which the valuable minerals are those of the base metals, the precious metals being incidental constituents, and ores in which the gold and silver are of primary importance, the basemetal minerals, if present, being of little or no value. The first class ...

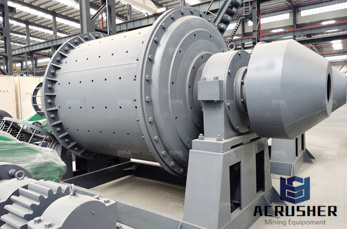

gold flotation mill. Gold Ore Ball Mills and Floatation Cells Mongolia YouTube Jun 11 2008 These Mongolian ASM formed a hard rock quartz ore mining coop and built this ball mill and and flotation cell circuit for gold recovery Improved Copper and Gold Recovery at KGHM StatEase In an effort to recover additional copper and gold at KGHM ...

Gold flotation process is composed of crusher, ball mill, classifier, mixing tank, flotation machine, thickener and dryer, JXSC provide gold ore processing equipment. Gold flotation process is composed of crusher, ball mill, classifier, mixing tank, flotation machine, thickener and dryer, JXSC provide gold ore processing equipment. ...

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Jun 11, 2008· These Mongolian ASM formed a hard rock quartz ore mining coop and built this ball mill and and flotation cell circuit for gold recovery. ... Gold Ore Ball Mills and Floatation Cells, Mongolia ...

Nov 13, 2019· Working principle of gold ball mill. The main parts of the gold ore ball mill includes the feeding, the supporting device, the rotating part, the unloading device and the transmission device. Working principle: gold ore ball mill is a lowspeed rotary cylinder horizontally mounted on the bearing. In the rotary cylinder, there are heavy steel balls.

Flotation Cell And Processing Gold Ore Ball Mill For Sale

Nov 19, 2011· A custom mill in MT, USA milling gold and silver ore through: Jaw crusher, Cone Crusher, Ball Mill, Jig, Shaker Tables, and Flotation Cells. This mill is capable of milling gold, silver, copper ...

mining machine supplier of ore ball mill ball mill gold ore flotation. Ball MillOre Grinding Mill Types and PriceJXSC Mining. May 10, 2019· Factors Influence Ore Grinding Mill Efficiency Abstract The grinding efficiency is the most important parameter to evaluate machine performance. This article discussed the factors that influence grinding ...

gold ore flotation cell ball mill flotation cell,Ball Mill Gold Flotation Cell Gold Ore Flotation Cell E6 good ore dressing flotation machine gold cil process good quality new flotation cellhe role of activators in froth flotation multibody 2017 froth flotation is a good example of an engineering system in that the various basic principles 4 mechanics of flotation 5 chemicals of flotation 6 ...

Gold Stryker® GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS7000LDuses a large 25 HP Honda Industrial engine for many years of trouble free use.

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an ore. Tailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

WhatsApp)

WhatsApp)