Graphite to 2020 charging ead?

Sep 10, 2015· Graphite hit the headlines again in 2015 when Tesla Motors began building its lithiumion battery "gigafactory" near Sparks, northern Nevada at .

WhatsApp)

WhatsApp)

Sep 10, 2015· Graphite hit the headlines again in 2015 when Tesla Motors began building its lithiumion battery "gigafactory" near Sparks, northern Nevada at .

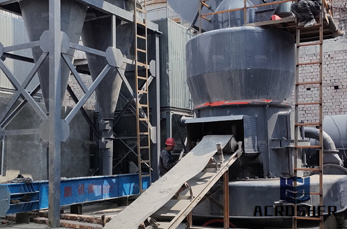

Apr 26, 2013· Graphite Crusher,graphite beneficiation,graphite crushing process . Graphite Mining,Broken,recycling . Environmental impacts from graphite mills consist of air pollution including fine particulate exposure of workers and also soil . »More detailed

spherical graphite milling equipment •China are seeking to integrate downstream into manufacturing of coated spherical graphite to control the entire battery chain process •Meanwhile, the rest of the world are looking to diversify supply away from Chinese sources Source: Benchmark Mineral Intelligence. Uncoated spherical graphite supply

Spherical graphite is a crucial ingredient to the efficient operation of lithium ion batteries (LiB). Spherical graphite is the key component of the anode of a LiB which without, the LiB would not function. Historically SPG has been derived from synthetic graphite, a significantly more costly option when compared against natural flake graphite ...

The Miller hydrothermal lumpvein historical graphite mine is located 80 km west of Montreal in the Grenville Township and exhibits extremely high purity graphite grading Cg. We have shown that the graphite could be suitable for use in nuclear reactors, with a calculated EBC of ppm, as compared to the required maximum levels, typically between 1 and 3ppm.

Introduction to Mineral Processing. ... This process is based on the ability of certain chemicals to modify the surface properties of the mineral(s). Other chemicals are used to generate the froth and still others are used to adjust the pH. Certain chemicals are even capable of depressing the flotation of minerals that are either to be ...

imported graphite, and the development of synthetic graphite manufactured from coal in electric furnaces, or as a byproduct of blast furnaces, marked the end of graphite exploration and mining in New Jersey. During the peak of mining activity, four separate mills were in operation to process the ore. These were located at the

There are three principal types of natural graphite, each occurring in different types of ore deposit The mineral graphite is an allotrope of carbon. Unlike diamond (another carbon allotrope), graphite is an electrical conductor, making it a semimetal. Graphite is the most stable form of carbon under standard conditions. As a result it is used in thermochemistry as the standard state for ...

At five towns in two provinces of China, Washington Post journalists heard the same story from villagers living near graphite companies: sparkling night air, damaged crops, homes and belongings ...

Due to the layered structure of graphite, atoms or small molecules can be introduced between the carbon layers (intercalation). During this process a socalled expandable graphite salt or GIC (Graphite Intercalation Compound) is produced. Outstanding expandable graphite grades have a high proportion of intercalated layers. Usually sulphur

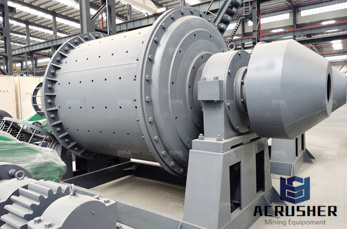

Natural graphite is obtained from an abandoned opencast mine and purified by a simple, ecofriendly andaffordable beneficiation process including ball milling and flotation process. Both raw ...

Oct 01, 2014· The beneficiation process can be defined as a treatment process of ore which results in a more concentrated form of the product. It is often used in the preparation of iron ore for smelting. This is an essential process as it helps improve the yield from a deposit of ore, thereby increasing the ...

Froth Flotation (Sulphide Oxide) ... If there is overgrinding problem in the process you will have graphite slime coating on clay particles and this makes those clay particles behave like graphite particles and will report to the floated products. ... ENTER our Mining Equipment'' Store.

May 17, 2016· Graphite Processing secrets. With the growing interest in the Graphite industry and more new players entering the mining sector with their eyes focused on graphite it is becoming important to shed ...

The process is called Chemical Vapor Deposition (CVD). The resulting material is ultra pure anisotropic graphite possessing near theoretical density (no pores), excellent thermal conductivity and high strength. Pyrolytic graphite is used as a nonpermeable coating on sintered graphite.

Approval process: On 26 October 2016, Pirie Resources Pty Ltd lodged a mining proposal (MC 4393) under the Mining Act 1971 or the Campoona Graphite Project in the Cleve Hills of Eyre Peninsula. Mining Proposal and Management Plans. Main Document (PDF 19 ) Appendices (PDF 61 ) Addendum (414 KB)

The Company holds of a Mining Licence and between 70% and of adjacent graphite prospecting licences at Lindi Jumbo with an enduring option to acquire the remaining 30% share. A highgrade graphite Mineral Reserve has been delineated within the Mining Licence Application area.

The beginnings of the revolutionary froth flotation process are associated with graphite mining. Included in the EMJ article on the Dixon Crucible Company is a sketch of the "floating tanks" used in the ageold process of extracting graphite. Because graphite is so light, the mix of graphite and waste was sent through a final series of water ...

Graphite machining can be challenging. Especially if you are not prepared to work with it''s unique and messy properties. As a custom graphite machining facility as well as a supplier of graphite material blanks, we have answered may customer questions over the years about the difficulty of machining graphite correctly.

Graphite is ideal for numerous applications as it has properties found in both metals and nonmetals. Flake graphite accounts for approximately 40% of global natural graphite supply. The supply of flake graphite is concentrated primarily in China, with Brazil, North Korea, Canada and India accounting for nearly all of the remainder of production.

Spherical graphite is the product that most graphite companies are hoping they will be economically able to produce in line with an expected battery demand boom from portable devices and, more importantly, electric vehicles. The process is well known now, but only China produces spherical graphite ...

Modern graphite manufacture commences with a high molecular weight hydrocarbon, often natural pitch or a residue of crude oil distillation, which is first converted to coke by heating in the absence of air. This is long and complex process, usually taking several weeks to perform.

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Graphite deposit quality Many graphite explorers espouse the notion that biggest is best. Although resource tonnes and graphitic carbon content (grade) are important metrics in evaluating mining projects, the overall picture is more complex. Key attributes include lake size distribution, the purity of the graphite.

WhatsApp)

WhatsApp)