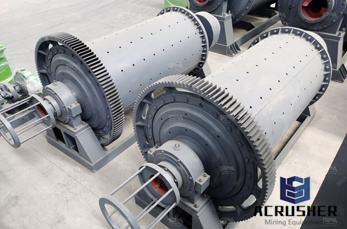

ball size calculation for ball mill

Ball Mills Mine Engineer . Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball ...

WhatsApp)

WhatsApp)

Ball Mills Mine Engineer . Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball ...

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill''s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size .

On the subject of ball size and ball charge in a grinding mill, . METHOD FOR ESTIMATING THE BALL CHARGE OF A GRINDING MILL . METHOD FOR ESTIMATING THE BALL CHARGE OF A GRINDING MILL . . a processor which is arranged to calculate a ball charge estimate using a Kalman filter which uses .

Ball Size as Initial Charge. Commercial ball sizes 10 – 150 mm; Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge. For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed,, d↓V = K√F

how to calculate size of ball mill in cement plant how to calculate size of ball mill in cement plant, ball mill, ball milling, ball mill price, cement ball mill this page is about the minevik ball mill for silicate, cement, » powder grinding plant » all grindinghow to calculate size of ball mill in cement plantcrusher, cement mill, the .

Ball mills are predominantly used machines for grinding in the cement industry ... cement plant The benefits that can be achieved due to the optimisation of .... Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power.

Telephone: Telephone: Contact Person: Fax:— Well,there is no precise calculation method that can accurately calculate the specific capacity of the cement ball are...

How to Size a Ball Mill Design Calculator Formula Mineral ... Mar 31, 2016 ... Estimation based on FLSmith (Krebs) Capacity Correlation. Ideally, design value should not exceed 13 psi.

Jun 25, 2018· Mill effective diameter = m . 335 is a constant used for dry grinding with steel balls in the mill. Actual size of media is taken is lower than the calculated value. It is around 80 to 90 mm. If you Wants to reduce the maximum ball size, thenreduce the feed size by using pregrinding operation.

ball mill calculation for cement plant:cement ball mill design calculation tisshoo cement ball mill design capacity calculation Cement Ball Mill is the equipment used diameter by 32 Ft long ball mill in a Cement Plant Photo of a series of Get Price And Support Online Calculate Top Ball Size of Grinding Media Equation . More Detail

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill .

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

The ball mill discharge is feed to the top of the SKSSeparator. Cement grinding capacity of Ball mill increases by adjustment of air gap in the V Separator with proper air distribution. Maintaining uniform air gap between plates and steps in the VSeparator increases production of cement mill.

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Mar 03, 2015· Ultimate particle size depends entirely on how hard the material you''re grinding is, and the time how long the Ball Mill runs. Our Ball Mills have been used to .

Ball mill media charge calculation pdf, how to calculate charge in ball mill, Volume in Ball or Rod Mill how to calculate size of ball mill in cement plant. Get Price. How To Calculate Grinding Media In A Ball Mill In. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant ...

classification and generate a product with a narrow particle size distribution. Ball Mill Internals Ball mills have been conventionally an integral part of most cement plants for grinding raw materials, coal and clinker. The major technological advancements in conventional ball mills have been the improvement in

Jun 19, 2015· However, within the range of normal (North American) operating practice ( 35 40% mill loading, and 70 80% of critical speed) and for ballsize approximating the lifter height, the ...

If P is less than 80% passing 70 microns, power consumption will be. Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work ...

Jun 08, 2013· formula for calculation of degree of filling in ball mill BINQ ... CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D) ... formula to calculate ball mill volume loading ... capacity calculation of cement mill; Cement Mill Notebook Scribd Cement Mill Notebook ... Angular velocity of the mill tube in radial/second. w.

Bond ball mill grindability test for overflow wet ball mills. An approach was proposed by Erdem (2002) for dry multicomponent cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a

Cement ball mill, cement clinker grinding mill for cement plant. Cement ball mill is used to grind crushed cement clinker, gypsum rock . coal etc. for cement mill in cement production line is of low cost, high capacity etc.

Calculate Top Ball Size of Grinding Media FRED C. BOND Equation Method Previous Next Although it was developed nearly 50 years ago, Bond ''s method is still useful for calculating necessary mill sizes and power consumption for ball and rod mills.

WhatsApp)

WhatsApp)