Virtual Cement Plant Tour | Portland Cement Association (PCA)

Virtual Cement Plant Tour | Portland Cement Association (PCA)

WhatsApp)

WhatsApp)

Virtual Cement Plant Tour | Portland Cement Association (PCA)

Process Discretion: Wet process, Semidry process, Dry process and Finish process. The environmental im pact of the cement production and its variations between different cement plants.

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Volume 3, Issue 5, November 2013 385 Abstract— formalized by French and British engineers in the 18th This paper analyzes an existing processing management system in a cement factory in India. During the last two decades (80''s and 90''s), major technological advancements took place in design of cement plant equipment/systems. The

Jul 31, 2013· Now let us discuss wet process and dry process PROCESS:In the wet process, first the clay is purified by washing in a wash .

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Sep 14, 2014· Category People Blogs; Song Herbal Pekoe13953; Artist Joseph Saba, ASCAP|Stewart Winter, ASCAP; Album VH029 Infonewsdramatainment

Mississauga Cement Plant Processing Video . CRH Canada''s Mississauga Cement plant is proud to share this video demonstrating our Cement making process. For additional information on our cement making process, visit our process page. In the community for over 60 years.

Plants that burn waste fuels enjoy a negative fuel cost (they are paid by industries needing to dispose of materials that have energy content and can be safely disposed of in the cement kiln thanks to its high temperatures and longer retention times). As a result, the inefficiency of the wet process is an advantage—to the manufacturer.

The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay. Suitable reserves can be found in most countries. These raw materials are extracted from the quarry by blasting. They are then crushed and transported to the plant where they are stored and homogenized.

A typical plant for Portland cement production had been analysed for this study, located in Balsa Nova, PR, with an installed production capacity of million tonnes of cement per year and employing the coprocessing since 1993. The cement industry waste coprocessing has been studied by several authors in order to decrease environmental ...

Mar 29, 2012· Lucky Cement Limited (LCL) is Pakistan''s largest producer and leading exporter of quality cement with the production capacity of tons per annum. The Company is listed on Karachi ...

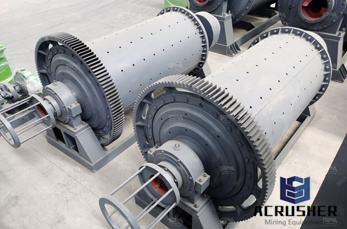

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

January 2019 This handbook has been superseded by the Cement Plant Operations Handbook 7th Edition. Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement .

Stationary Concrete Plant. The stationary concrete plant is designed for produce highquality concrete. It has the advantages of large output, high efficiency, high stability and high specification. Stationary Concrete Batching Plant adopts reliable and flexible components, making it easy to maintenance and owning a low failure rate.

In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60%, the raw ...

This paper explores the use of process integration techniques to improve the energy efficiency of cement plants, focusing on the dry route cement production and the integration of alternative fuels. Flow sheeting modeling, Pinch Analysis and mixed integer linear optimization techniques are applied to study an existing cement production facility.

What to do with "concrete waste" at any type of concrete plant. ... a lot of times mechanics build in environmental fees for handling and processing your unwanted stuff. Do the same! ... Your best solution for excess concrete materials at any concrete plant starts with simply addressing the issue, and developing a plan. Without a plan, your ...

Perry Videx offers used and refurbished Plant Mineral Processing, Mining, Cement, used and refurbished Plants

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference. NOTE:

Welcome to the Cement Kiln Pyroprocessing course. The course will be published over a 6 week period and will provide 24 lectures on different topics associated with pyroprocessing in cement kilns. There will also be exercises and quizzes to assist with the learning process and exams at the end of ...

May 27, 2019· New coprocessing cement plant inaugurated in China Published on: 27 May 2019 . Guangxi Guigang Cement Kiln Coprocessing solid waste project is the largest of its kind in China..To read the rest of this article, please login with your CW Group Single SignOn first. If you do not already have a CW Group account, please register.

A cement plant consumes 3 to 6 GJ of fuel per tonne of clinker produced, depending on the raw materials and the process used. Most cement kilns today use coal and petroleum coke as primary fuels, and to a lesser extent natural gas and fuel oil. Selected waste and byproducts with recoverable calorific value can be used as fuels in a cement kiln ...

WhatsApp)

WhatsApp)