MACHINING OPERATIONS AND MACHINE TOOLS

Figure (a) horizontal kneeandcolumn milling machine ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Machining Centers

WhatsApp)

WhatsApp)

Figure (a) horizontal kneeandcolumn milling machine ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Machining Centers

SHANGHAI NMN MACHINERY CO., LTD is one hightech enterprise, ... short note on hammer mill; write short notes on millig machine; » Learn More. Notes on Cnc Scribd. Notes on Cnc Download as PDF File (.pdf), Text file (.txt) or read online. Scribd is .

Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. Lathe Machines are used in metalworking, woodturning, metal spinning, thermal spraying, glass working, and parts reclamation.. The various other operations that you can perform with the help of Lathe Machine can include sanding, cutting, knurling ...

Tool wear Index, feed marks and surface finish Type of wear depends MAINLY on cutting speed •If cutting speed increases, predominant wear may be "CRATER"wear else "FLANK"wear. • Failure by crater takes place when index h k reaches value, before flank wear limit2of h f .

Form milling is the process of machining special contours composed of curves and straight lines, or entirely of curves, at a single cut. This is done with formed milling .

Wear glasses, short sleeves, no tie, no rings, no trying to stop the work by hand. Stop the machine before trying to check the work. Don''t know how it works? –"Don''t run it." Don''t use rags when the machine is running. 1. Remove the chuck key from the chuck immediately after use. Do not turn the lathe on if the chuck is still in the ...

A very simple cnc milling program example which shows how a simple slot can be machined. Another such program example which mills a pocket the same way but in a taper is here CNC Milling Machine Programming Example for Beginners.. Slot Milling Program Example

a short note on implementing new machine instructions . Instructions How To Use a Milling Machine ... Therefore, the RPM for a l/2inchdiameter end mill machining aluminum revolves at 2,400 RPM and the feed rate should be ...

Oct 09, 2018· This is why a milling machine has wide application in production work. This is better for other machines as regards accuracy and better surface finish. And also it is designed for machining a variety of tool room work. Milling Machine Operations. The 15 different types of milling machine operations are as follow: Plain Milling Operation

May 08, 2016· Shaper machine works on the quick return mechanism. It is used to shape the metal or make flat surfaces, making grooves and slots. It cuts the metal in one stroke in back motion or in froth motion and the remaining one is useless. The working of shaper machine can be described as follow.

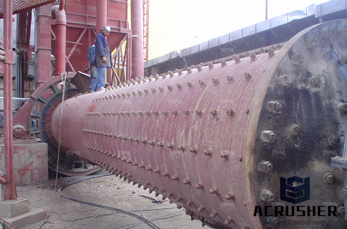

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Oct 21, 2009· Introduction: Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges. Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be used for drilling, slotting, making a circular profile and gear cutting by having suitable attachments.

Mar 23, 2018· This is a really simple and short tutorial that will help you start making PCBs using the Roland PCB milling machine (Roland Modela MDX20). And you will be able to start making beautiful PCBs for your projects in no time :) This tutorial uses the Fab modules software bundle to send the design files to the PCB miller.

Tooling Milling Heads. everything in pictures. Master Gearhead Motor. They are subject to withdrawal, change and prior sale without notice. All orders received are binding only when they have been accepted and acknowledged by us in writing.

Grizzly Industrial®, Inc. is a national retail and internet company providing a wide variety of highquality woodworking and metalworking machinery, power tools, hand tools and accessories. By selling directly to end users we provide the best quality products at the best price to professionals and hobbyists.

Milling machine 250,000 Rayya Co. purchases and installs a machine on January 1, 2018, at a total cost of 105,000. Straightline depreciation is taken each year for four years assuming a sevenyear life and no salvage value.

The workpiece to be drilled is fastened to the milling machine table by clamps, vises, or angle plates. 20. Boring : Various types of boring tool holders may be used for boring on the milling machine. the boring tools being provided with either straight shanks to be held in chucks and holders or taper shanks to fit collets and adapters.

Turret milling machines, with the exception of CNC, have remained virtually unchanged for 50 years serving as longlasting general machine tools.

It''s a "human" thing. Milling machines help to bring out the creative flow in hobbyists and professionals alike. My easytoread guide doesn''t assume you know anything about choosing the best milling machine. This short introduction may also serve as a good refresher familiar with the tech. In this guide, we show you the best milling ...

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

plain horizontal milling machine in that it is of the ram type;, the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column. The ram can be moved in or out to provide different positions for milling operations. (2) Ramtype Milling Machines. (a) Description. The ramtype milling machine is ...

Dec 05, 2014· 15 Short Answer Milling Machine Questions (with Answers) Milling machine is a very important machine tool used in mechanical operations. Here we are presenting some Very Short Answer Questions related with milling machine.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operations.

Milling Machines A milling machine is a power driven machine that cuts by means of a multitooth rotating cutter. The mill is constructed in such a manner that the fixed workpiece is fed into the rotating cutter. Varieties of cutters and holding devices allow a wide rage of cutting possibilities.

WhatsApp)

WhatsApp)