Sand mining: the global environmental crisis you''ve never ...

Feb 27, 2017· From Cambodia to California, industrialscale sand mining is causing wildlife to die, local trade to wither and bridges to collapse. And booming urbanisation means .

WhatsApp)

WhatsApp)

Feb 27, 2017· From Cambodia to California, industrialscale sand mining is causing wildlife to die, local trade to wither and bridges to collapse. And booming urbanisation means .

Industrial sand and gravel is used to make glass, as foundry sand and as abrasive sand. For some applications, it is the silica content (quartz) of sand that makes it so valuable. The silica itself is needed to make products such as glass.

May 11, 2015· Silica sand mining has minimal environmental impact, involves virtually no public health risk, and is an important part of domestic energy production that has substantial economic benefits. Heartland Policy Study No. 137, "Environmental Impacts of Industrial Silica Sand (Frac Sand) Mining," documents the following facts:

Jan 01, 2014· This video may can help you. https:// In the silica sand production line, Jaw Crusher is the coarse silica sand crushing machine ...

Community concerns related to general mining activities include increased traffic,noise, and risk of accidents. Health Impact Assessment (HIA) is a process that could lead to a more complete evaluation of all of the risks associated with the frac sand mining process. Crystalline Silica Toxicological Summary Sheet (PDF)

Introduction. Sand and gravel are used extensively in construction. In the preparation of concrete, for each tonne of cement, the building industry needs about six to seven times more tonnes of sand and gravel (USGS, 2013b). Thus, the world''s use of aggregates for concrete can be estimated at billion to billion tonnes a year for 2012 alone.

Although exact circuit configurations vary among the operations, a typical oil sands mining facility consists of the following unit operations: an openpit (or surface) mine. a bitumen production circuit where the bitumen is separated from the solids and water. a tailings storage facility or pond, where solids are stored and process water is ...

SAND AND SAND MINING Part I. Source: Unknown Uses of sand This resource is sand, not sand and gravel. Its primary source is sand dunes, therefore Michigan ranks third in the US in industrial sand production. Silica sand is the major component of glass, foundry molds, and abrasives. It is also used in ceramics, on golf courses, and as a filter ...

Industrial sand mining overview. Sand mining has occurred in Wisconsin for more than 100 years. Recent growth in the petroleum industry has created a high demand for sand that can be used for hydraulic fracturing, a technique used to extract natural gas and crude oil from rock formations in .

Silica. Also called silica sand or quartz sand, silica is silicon dioxide (SiO 2). Silicon compounds are the most significant component of the Earth''s crust. Since sand is plentiful, easy to mine and relatively easy to process, it is the primary ore source of silicon. The metamorphic rock, quartzite, is another source.

Manufacturing Process Of Sand Mining Machinery. Process For Quartz Sand Manufacturing Iaspired Co Inmanufacturing process of quartz sand manufacturing process of silica sand This is the most common method used to produce quartz glass in a continuous procedure to start the robo sand plant Jun 7, 2017 Silica sand manufacturing process and the equipment for silica ; Dolomite ...

Oil sands are a loose sand deposit which contain a very viscous form of petroleum known as sands are actually found all over the world and are sometimes referred to as tar sands or bituminous sands.. Alberta''s oil sands contain on average about 10% bitumen, 5% water and 85% of the solids are coarse silica sand.

Industrial Sand Mining 101 ... That is an important part of the scientific process. ... To be classified as industrial sand, the sand source needs to contain a large percentage of very pure silica sand, with uniform grain size and clean, wellrounded grains. The siliconoxygen atoms that make up pure silica quartz form one of nature''s hardest ...

Industrial Sand Mining 101 Into The Outdoors. Industrial Sand Mining 101 That is an important part of the scientific process. To be classified as industrial sand, the sand source needs to contain a large percentage of very pure silica sand, with uniform grain size and clean, wellrounded grains.

"Frac sand" is a highpurity quartz sand with very durable and very round grains. It is a crushresistant material produced for use by the petroleum industry. It is used in the hydraulic fracturing process (known as "fracking") to produce petroleum fluids, such as oil, natural gas and natural gas ...

Frac Sand (often called "silica" or "silica sand"): A naturally occurring silica sand used as a proppant to keep an induced hydraulic fracture open during the fracking process. Frac Sand Mineralogy: Frac sand must be greater than 99% quartz to be suitable for use as a proppant.

Metallurgical ContentThe Silica Sand FlowsheetSANDSTONE DEPOSITSOPEN SAND PIT (Dry)OPEN SAND PIT (Wet)PRIMARY CLASSIFICATIONATTRITION SCRUBBINGSECONDARY CLASSIFICATIONCONDITIONING AND FLOTATIONFINAL DESLIMINGDRYING AND DRY GRINDINGSummary of the Silica Sand Processing Plant EquipmentA Flowsheet for Beneficiation of Silica .

Silica sand is found in the southeastern portion of the state. Five mines are currently known to extract silica sand for industrial applications. An unknown number of silica sand mines produce silica sand for construction and agricultural uses. Silica sand mines producing frac sand may or may not process the sand .

Jun 02, 2012· of sand in the process. Wisconsin possesses highquality sand resources and therefore is seeing a substantial rise in mining permit requests to mine for frac sand. Consequently, the topic of sand mining in Wisconsin has generated interest from regulators, legislators, local government, and the general public. Purpose of this document

Silica sand mining process equipment is widely used both domestic and abroad in Silica sand may be produced by silica sand mining process from sandstones, read More . N A Process Of Sand Mining sand and gravel mining process – Grinding . Kim 144200 Construction sand gravel N. 2 368 26 913 908 382 20 » Learn .

RED WING — Demand for silica sand has driven what some are calling "the new gold rush." Since 2008, Wisconsin has built 16 silica sand mines. Eleven more have recently been approved and at least ...

Clean sand is stockpiled until it can be loaded into trucks for final sorting and drying offsite. (Some mines sort and dry sand onsite rather than sending it out.) Because the sand still contains moisture when it is stockpiled, drain tiles beneath the piles channel water to a lined processwater pond.

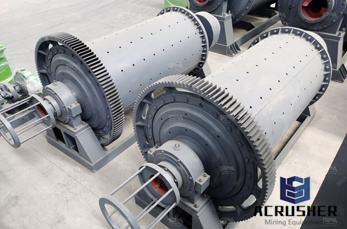

The main purpose of silica sand is the product expansion to make glass, casting, ceramics and refractory materials, smelting and other relevant. However, processing, processing for silica sand, according to different purposes appeared many for silica sand mining equipment, which is widely is silica sand crushing machine, milling machine and so on.

state. Five mines are currently known to extract silica sand for industrial applications. An unknown number of silica sand mines produce silica sand for construction and agricultural uses. Silica sand mines producing frac sand may or may not process the sand onsite. Offsite processing plants that receive silica sand from various mining ...

WhatsApp)

WhatsApp)